At Ant & Grace, creativity is never still. What began with 3D printed home décor — gothic centrepieces, modern geometric ornaments, sculptural vases, and atmospheric wall art — is evolving into something even more exciting: our exploration into metal casting.

Metal has a timeless presence that’s impossible to ignore. It feels strong, permanent, and full of character. For some of our designs, especially gothic pieces with their dramatic shapes, transforming them into metal opens an entirely new dimension. And for our minimalist pieces, metal brings sophistication and weight that offers a completely different aesthetic.

This journey from 3D print to metal is one of experimentation, learning, and creative expansion — and today, we’re taking you behind the scenes.

Why Metal? The Allure of Durability and Drama

There’s something undeniably striking about metal décor. The moment you pick it up, you feel its weight, its cool surface, and its sense of permanence. Metal has been used in decorative arts for centuries — from medieval ironwork to Victorian ornaments to modern sculptural pieces.

What makes metal so intriguing for us is that it blends beautifully with our entire range:

🖤 Gothic pieces become moody, dramatic, and authentic — almost relic-like.

◼️ Modern designs look sculptural and high-end, perfect for minimal interiors.

📐 Geometric ornaments benefit from sharp edges and crisp metallic finishes.

🌿 Nature-inspired pieces gain texture, depth, and an organic, cast-metal aged feel.

Metal has presence — and transforming our 3D prints into metal was the natural next step.

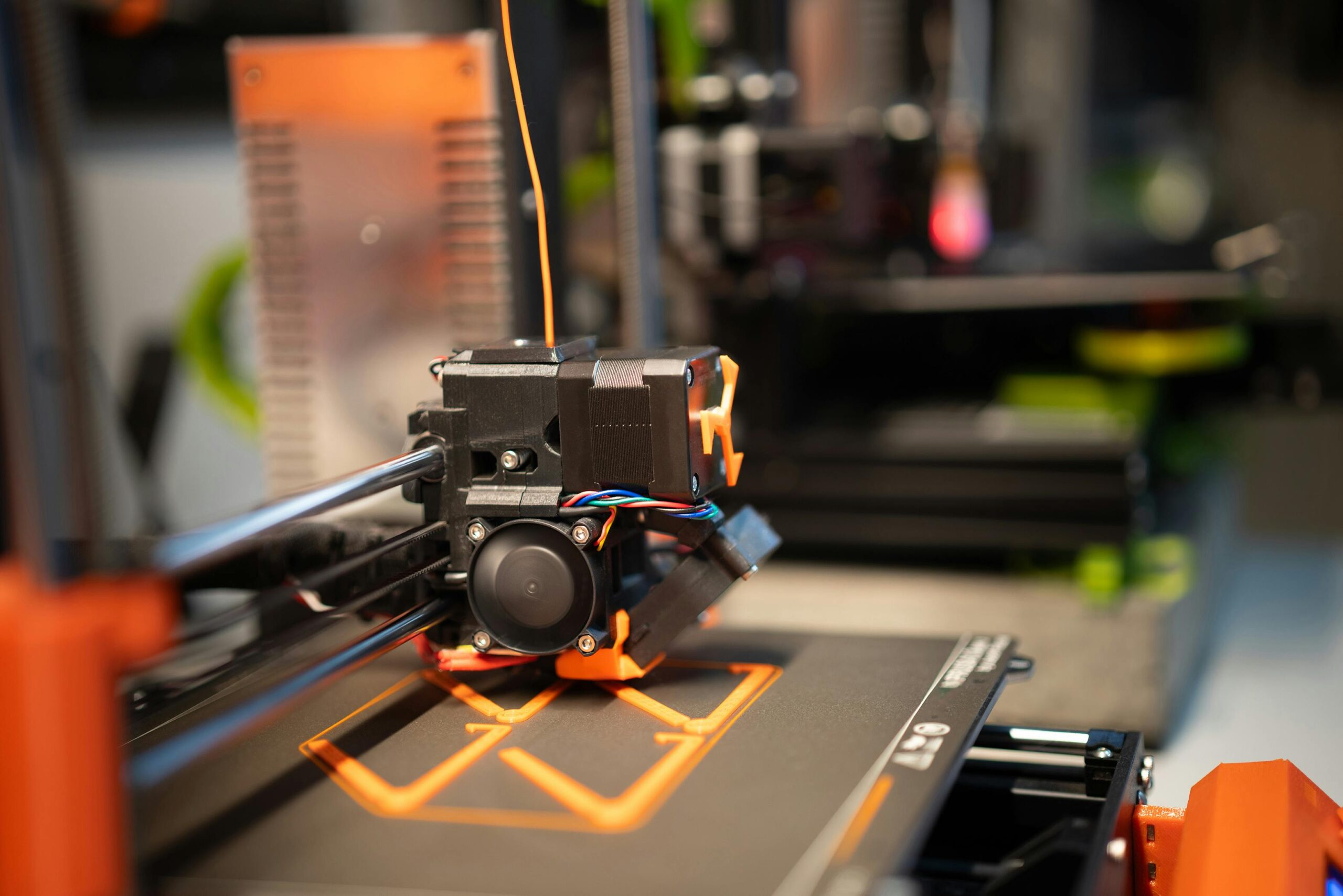

Step One: Using 3D Prints as Mould Masters

The beauty of 3D printing is its precision. Every curve, texture, and detail can be recreated exactly in a printed model — which makes it the perfect starting point for metal casting.

We begin by creating a strong, clean 3D print of the design. This becomes the “master” — the original form used to make the mould.

For gothic pieces, this may be:

-

an ornate skull

-

a filigree wall plaque

-

a gothic candle holder

-

a dramatic medieval-inspired emblem

For contemporary designs, it might be:

-

a smooth minimalist sculpture

-

a geometric orb

-

a modern vase

-

a decorative abstract form

The print must be flawless — because every detail transfers into the metal.

We clean, refine, and prepare the piece until it’s worthy of being cast.

Step Two: Exploring Silicone Moulds

Once the master is ready, we experiment with silicone moulding. Silicone moulds capture detail incredibly well, making them perfect for pieces with:

-

intricate gothic patterns

-

stylised shapes

-

delicate textures

-

sharp geometric angles

This is where we start to see the crossover between modern technology and traditional craftsmanship.

We pour silicone over the 3D printed master, allow it to cure, and then carefully remove the print to reveal a perfect mould cavity.

This mould will be the foundation for metal casting — whether we’re using cold-cast metals or exploring full molten casting techniques.

Step Three: Cold Casting — The Bridge Between 3D Print and Solid Metal

Cold casting is one of the most exciting techniques for us because it allows the look and feel of metal with far more flexibility.

Cold casting uses:

-

real metal powders (bronze, aluminium, brass, copper, etc.)

-

mixed into a resin

-

poured into the silicone mould

-

and polished to a metallic finish

The results can be incredible:

-

cold-cast bronze looks like aged museum-quality metal

-

aluminium creates a sleek modern shine

-

brass and copper give a warm, rich tone

-

steel powder offers dark, gothic depth

Once polished, sanded, and burnished, cold-cast pieces become nearly indistinguishable from solid metal — yet remain lighter, more affordable, and much easier to produce in small batches.

This method is perfect for gothic plaques, ornate mini sculptures, and luxury-feeling décor items.

Step Four: Metal-Infused Filaments — Hybrid Aesthetics

Another technique we’re exploring involves speciality filaments — PLA mixed with real metal powders. These include:

-

copper-infused PLA

-

bronze-fill filaments

-

brass-filled materials

-

iron-infused PLA (which can even rust naturally!)

These prints feel heavier, colder, and more metallic than standard filament. Once they’re sanded and polished, the metal particles rise to the surface and create:

-

metallic shimmer

-

brushed metal textures

-

aged patina effects

-

beautiful gothic darkening

-

high-end modern shine

This method blends our existing 3D printing workflow with new, more luxurious finishes.

Step Five: Early Experiments With Full Metal Casting

While still in testing, we’re slowly taking steps toward exploring lost-PLA casting, a method where:

-

A 3D print is made from a burnable filament

-

It’s encased in casting plaster

-

The PLA is melted away

-

Molten metal is poured into the cavity

This technique is used in jewellery and small metal sculpture making — and we’re studying how it can be applied to Ant & Grace designs in the future.

Imagine:

-

a gothic skull cast in pure brass

-

a geometric sculpture in aluminium

-

a custom modern ornament in polished bronze

-

a gothic wall emblem in iron

This direction opens up a world of possibilities — one we’re excited to grow into.

Why Metal Casting Complements 3D Printing So Perfectly

3D printing and metal casting might seem like opposites, but they work in harmony.

3D printing offers:

-

unlimited design flexibility

-

precision

-

quick prototyping

-

affordability

-

customisation

-

lightweight pieces

Metal offers:

-

weight

-

permanence

-

luxury

-

texture

-

traditional craftsmanship

-

natural ageing and patina

Together, they create décor that merges modern creativity with timeless material quality.

Gothic designs become more authentic.

Modern designs become more sculptural.

Abstract designs become more artistic.

It’s a blend of old and new — something we love exploring.

What This Means for Ant & Grace Customers

Our journey into metal casting means exciting things for the future:

-

limited edition metal pieces

-

dual material collections (print + metal)

-

higher-end gothic décor

-

modern metal sculptures

-

unique gift collections

-

custom metal commissions

It also means more experimentation, more creativity, and more ways to offer décor that feels meaningful, personal, and artistic.

We’re not replacing 3D printed décor — we’re expanding it.

Building onto it.

Enhancing it.

Exploring new textures and materials to complement the designs you already love.

What Comes Next

This journey is only beginning. Metal casting is a craft — one we’re learning step by step, mould by mould, experiment by experiment. But it’s a natural evolution for Ant & Grace.

It brings depth to gothic pieces, elegance to modern ones, and a sense of luxury that elevates everything we create.

And as we continue shaping our collection, we’ll be sharing the process with you — every success, every lesson, and every step deeper into this new creative territory.

Leave your comment

Related posts

The start of a new year always brings a quiet [...]

Home décor is changing. In a world where people want [...]